Welcome to Zenith Furniture

Zenith Furniture facility is spread over 200,000 square feet of workspace, with manufacturing plants located at Sinnar, Nagpur and Mysore. Our Design Engineers craft practical solutions tailored to the unique needs of various customers. By utilizing advanced technology, we develop specific 3D component and tooling models, curating the foundation for our manufacturing processes.

We specialize in panel processing using state-of-the-art technology. Our process incorporates software, to optimize panel usage by optimizing resources. Top brand engineered woods are used to craft the furniture to ensure premium quality, durability and aesthetics to be delivered with Customers delight.

Segments Served By Us

OFFICE

Our Office furniture is designed to enhance Professionalism, Productivity and Comfort in the workplace. This includes wide range of items such as Work station, Writing Tables, Ergonomic chairs, Filing Cabinets, Conference set ups, Pantry Furniture etc., each one crafted to support various office functions smoothly.

HOME

Home furniture combines functionality with aesthetic appeal, creating personalized and comfortable living spaces. Our offerings vary widely to suit different requirements, tastes, and ambience, with modern solutions to room, style, and household needs, enhancing comfort, convenience, and overall lifestyle.

INSTITUTIONAL

We provide educational furniture with ergonomic design to foster effective learning environments in schools, universities, training centres, and other educational hubs. Our furniture supports diverse teaching methods, promotes collaboration, encourages creativity, and enhances student engagement.

RETAIL

Retail furniture is crafted considering the aesthetics and ambience to make the shopping experience pleasant for the customers by showcasing products effectively, creating a niche market, optimizing the retail set-up, and enhancing customer satisfaction, engagement, and brand identity, while ensuring durability and functionality.

Vertical Integration

Vertical integration is a strategic approach where a company extends its operations into different stages of Production or Supply chain. This approach can enhance control, streamline processes, and potentially reduce costs. Here's a more detailed look at how it works:

Forward Integration

Forward Integration involves a company expanding into activities closer to the end consumer. For instance, a manufacturer might start opening retail stores to sell its products directly to customers. This approach helps the company gain better control over its distribution, improve customer relationships, and capture a larger share of the revenue.

Backward Integration

Backward Integration involves moving upstream in the supply chain. A company might acquire or develop suppliers for the raw materials or components it needs. For example, a furniture manufacturer might purchase a lumber mill to secure a consistent supply of wood and reduce dependency on external suppliers.

Benefits of Vertical Integration

Cost Reduction

By controlling more stages of production, companies can reduce costs associated with intermediaries and achieve economies of scale.

Quality Control

Companies have more direct oversight over the production process, leading to higher and more consistent quality, efficiency, and customer satisfaction.

Increased Efficiency

Streamlined operations and reduced lead times improve overall efficiency, cutting costs, increasing productivity, and enhancing customer satisfaction.

Market Control

Companies can better manage their supply chain and distribution channels, potentially leading to competitive advantages, cost savings, and market growth.

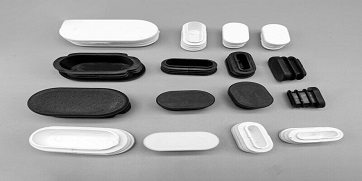

Plastic Injection Molding

In-house plastic injection moulding process to improve control, efficiency, product quality, cost-effectiveness, and faster turnaround times.

Dedicated Tools Room and In-House Fixtures

Managing a dedicated space for tool production and maintaining equipment internally to streamline operations.

Dedicated Plant for Metal Components and Pipes

Operating a distinct facility for manufacturing metal components and pipes to support wooden component plant and ensure quality.

Materials We Work Into

Engineering wood

Plywood

Edge Banding

Membrane

Acrylic

Plastic Injection Molding

.png)

Painting

Solid Surface

In house-Testing Labs

Zenith Solutions provide a full range of testing for hardware, raw material, filling materials, furniture components and more.